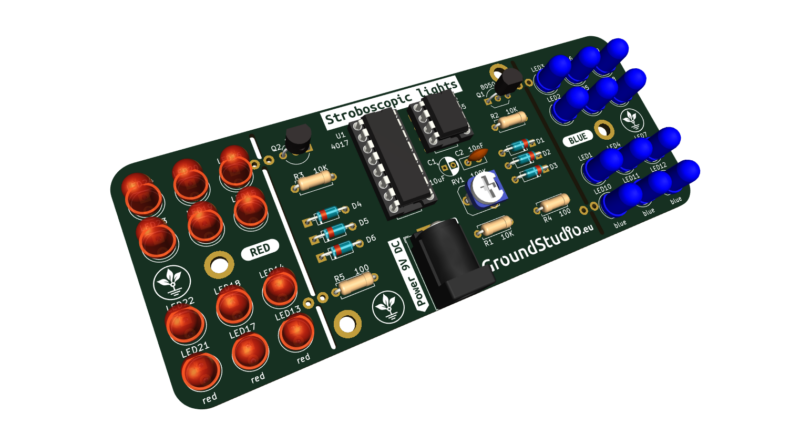

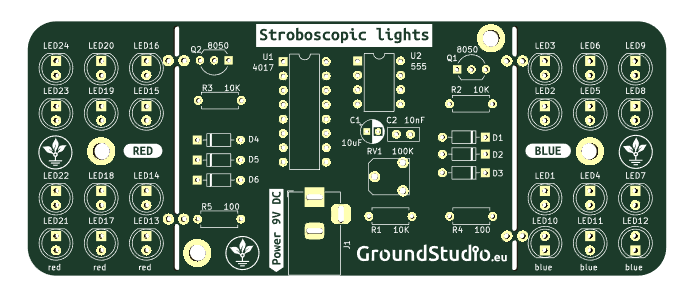

Stroboscopic lights

Introduction

This circuit simulates the stroboscopic lights of a police car. The light pattern consists of 3 blinks, alternating between each color.

List of tools required for assembly and operation,

not included in the kit

| Name | Image | Buy here |

|---|---|---|

| Soldering iron |  | |

| Solder wire |  | |

| Pliers |  | |

| Helping hands (device or a friend) |  | |

| Phillips Screwdriver |  | |

| Power supply* |

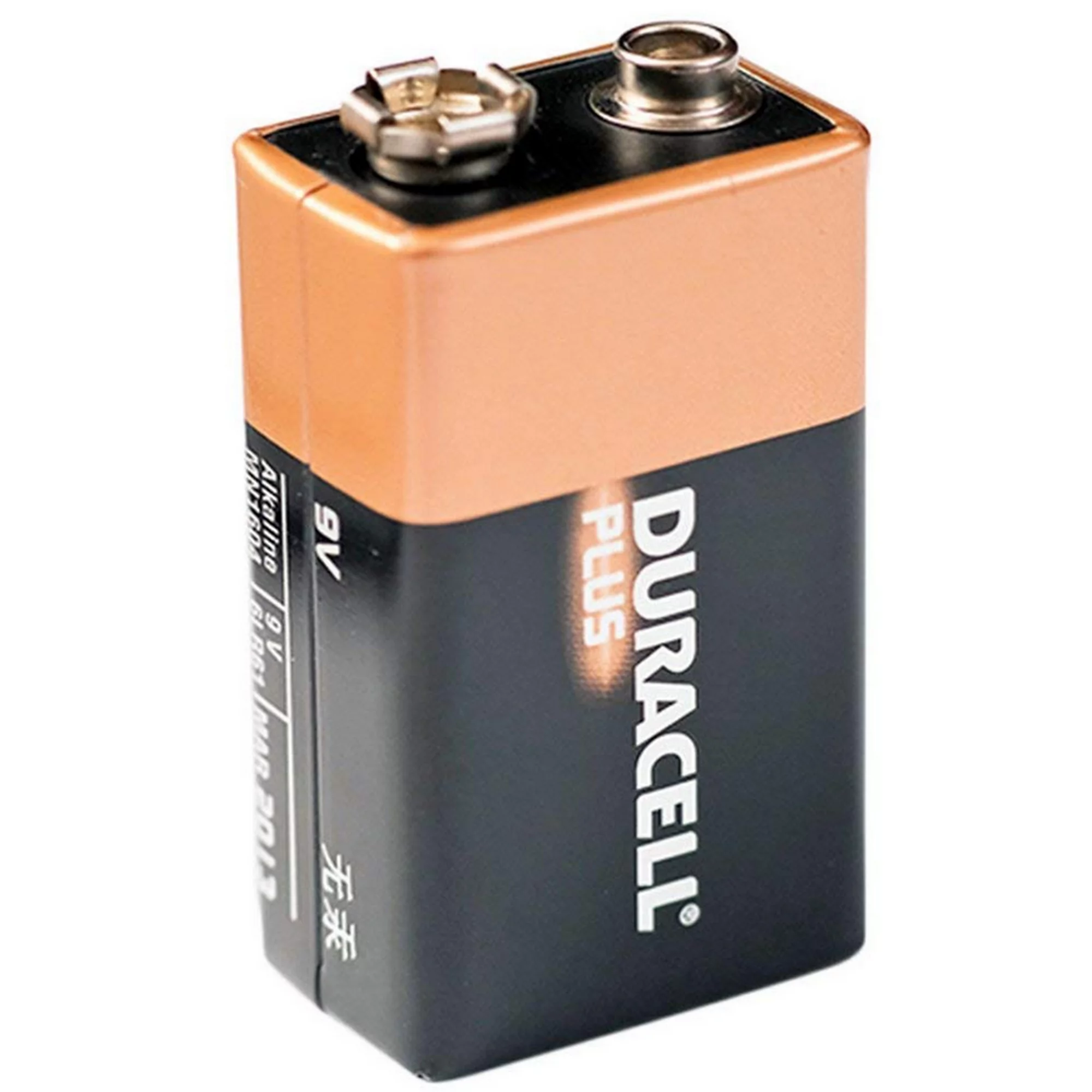

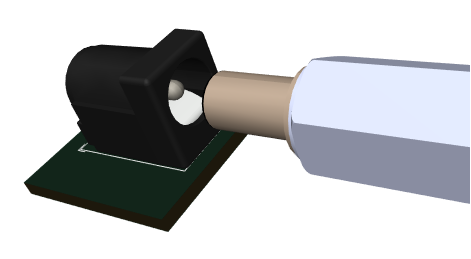

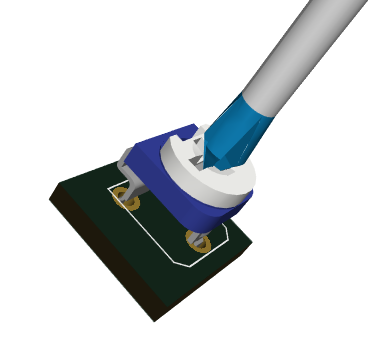

*To power the circuit, you‘ll need a 9V power supply with a DC connector.

Here are some suggestions:

| Connector for 9V battery + battery |  +  | |

| 9V power supply |  |

List of components included in the kit

| Quantity | Name | Details | Footprint | Image |

|---|---|---|---|---|

| 3 | Resistor | 10K | R1, R2, R3 |  |

| 2 | Resistor | 100R | R4, R5 |  |

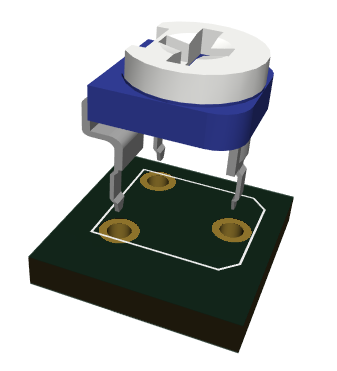

| 1 | Trimmer | 100K (104) | RW1 |  |

| 6 | Diode | 1N4148 | D1 – D6 | |

| 1 | Electrolytic capacitor | 10uF | C1 |  |

| 1 | Ceramic capacitor | 10Nf (10) | C2 |  |

| 2 | Transistor | 8050 | Q1, Q2 |  |

| 12 | LED | red, 5mm | LED1 – LED12 | |

| 12 | LED | blue, 5mm | LED13 – LED24 | |

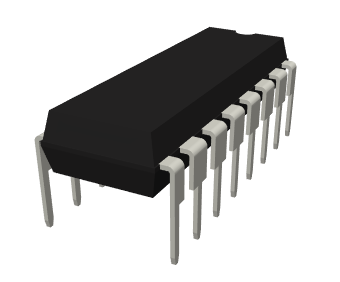

| 1 | Integrated circuit | NE555 | U1 |  |

| 1 | Integrated circuit | CD4017 | U2 |  |

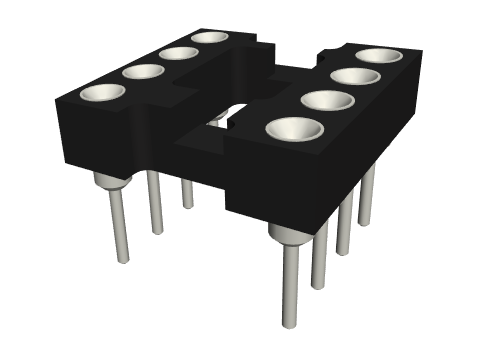

| 1 | Socket | 8 pins | U1 |  |

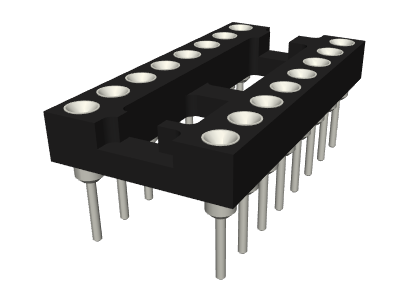

| 1 | Socket | 16 pins | U2 |  |

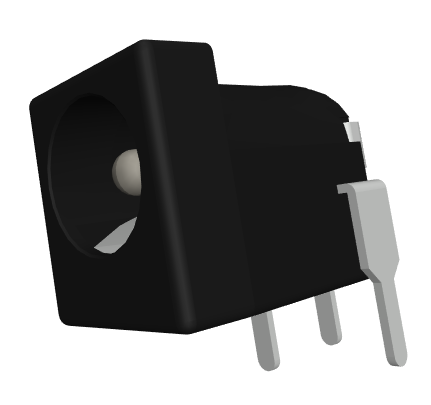

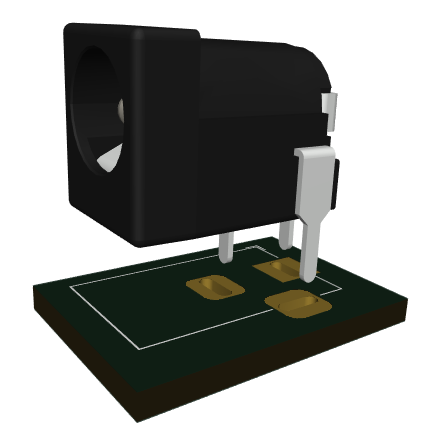

| 1 | Power connector | jack barrel, 9V | J1 |  |

| 1 | PCB |  |

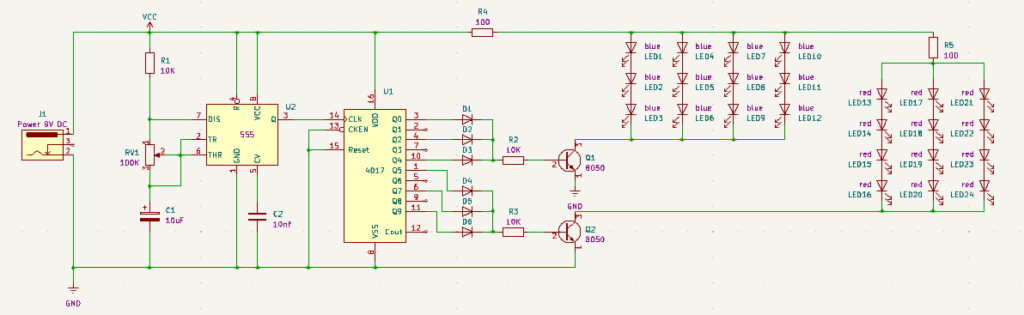

Schematic

Operating principle

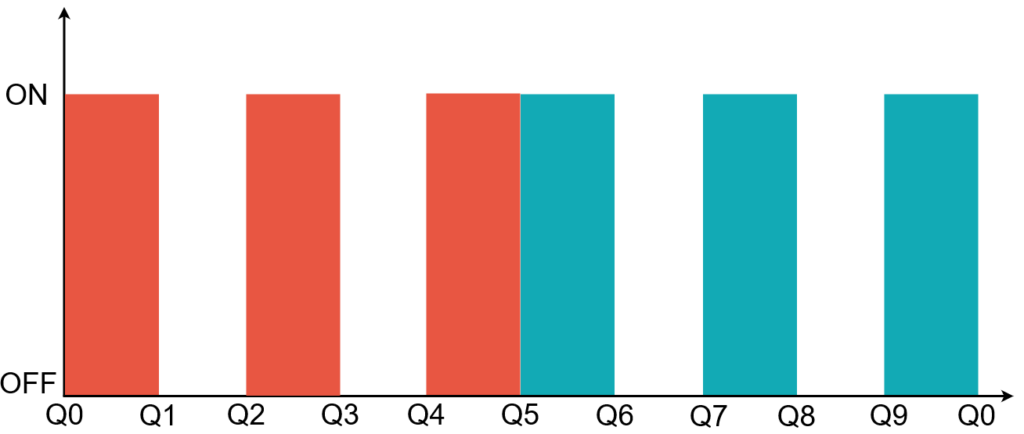

As seen in the example video, the light pattern consists of two phases:

- The red LED zone blinks 3 times.

- The blue LED zone blinks 3 times.

The 555 timer is used as an oscillator, along with R1, RV1, and C1. This circuit generates a continuous pulse on pin Q of the 555 integrated circuit.

The CD4017 acts as a decimal counter/pulse distributor. Specifically, with each pulse received from the timer at the CLK input, it sequentially sets one of the Q outputs, from Q0 to Q9, HIGH, while keeping all others LOW. As can be seen from the schematic, when the counter reaches Q0, Q2, and Q4, the blue LED zone lights up. Similarly, when the counter reaches Q5, Q7, and Q9, the blue zone lights up. When the counter is at Q1, Q3, Q6, Q8, all LEDs are off.

If you’re wondering why the red LEDs are connected in series in groups of 4 and the blue ones in groups of 3, it’s because the voltage drop on red LEDs is smaller than the one on the blue LEDs.

The graph below illustrates the state of the LEDs based on the Q output the counter has reached. Note that the 11th pulse from the timer causes the counter to restart the cycle at Q0, and the light pattern continues. The circuit will keep blinking as long as it is powered.

Notice the trimmer (variable resistor) RV1. Changing its resistance will modify the frequency of the pulses generated by the 555, making the LEDs blink faster or slower. In other words, RV1 controls the speed at which the LEDs blink.

From a mechanical standpoint, the circuit is composed of two LED zones, one red and one blue. These zones can be mechanically detached and connected with a soldered cable if you wish to relocate them. The connection pins are marked as B+ and B- for blue and R+ and R- for red.

Instructions for assembly preparation

| Step 0 | Read all the instructions, from beginning to end. |

| Step 0 bis | Reminder: It is very important to read all the instructions. |

| Step 1 | Make sure you have all the tools needed to assemble the kit. |

| Step 2 | Make sure you have all the components needed to assemble the kit. |

| Step 3 | To comply with the warranty conditions*, check/measure each component separately. |

Assembly instructions

| Step | Details | Image |

|---|---|---|

| Step 1 | Solder the resistors according to the markings on the PCB, regardless of orientation. Make sure you respect the values and markings | |

| Step 2 | Solder the IN4148 diodes, so that the terminal marked black on the diode (the negative one) corresponds to the one on the PCB | |

| Step 3 | Solder the electrolytic capacitors, so that the shorter terminal (the negative one, the cathode) corresponds to the hatched area on the PCB | |

| Step 4 | Solder the ceramic capacitors, regardless of orientation | |

| Step 5 | Solder the transistors, so that the cut-out markings correspond to those on the PCB | |

| Step 6 | Solder the trimmer according to the marking on the PCB |  |

| Step 7 | Solder the LEDs so that the longer terminal (the positive one) corresponds to the “+” sign on the PCB | |

| Step 8 | Solder the sockets so that the cut-out markings correspond to those on the PCB | |

| Step 9 | Solder the power connector according to the marking on the PCB |  |

| Step 10 | Insert the 555 and 4017 integrated circuits in their sockets, so that the cut-out markings correspond to those on the PCB | |

| Step 11 | Power the circuit with the chosen power supply |  |

| Step 12 | Check if the LEDs are blinking |  |

| Step 13 | Adjust the blinking frequency by slowly rotating the RV1 trimmer |  |

| Step 14 | Enjoy your stroboscopic lights! |  |

General assembly instructions for Warranty Compliance

As a precaution and to comply with the warranty conditions, we recommend testing each individual component before assembly. For example, resistors will be measured with an ohmmeter/multimeter. The warranty is for each individual component, not for the whole assembly. Since assembly is done by unauthorized personnel, under unknown conditions or at unknown stages of completion, we cannot assume any legal liability related to any consequences or operation of devices assembled by any third party.