Lumini stroboscopice

Introducere

Acest circuit simulează luminile stroboscopice ale unei mașini de poliție. Jocul de lumină constă în 3 blinkuri, alternând între fiecare culoare.

Lista cu uneltele necesare asamblării și funcționării

neincluse in kit

| Nume | Imagine | Cumpără |

|---|---|---|

| Letcon |  | |

| Fludor |  | |

| Clește pentru fire |  | |

| Helping hands (dispozitivul sau un prieten) |  | |

| Șurubelniță Phillips (în cruce) |  | |

| Power supply* |

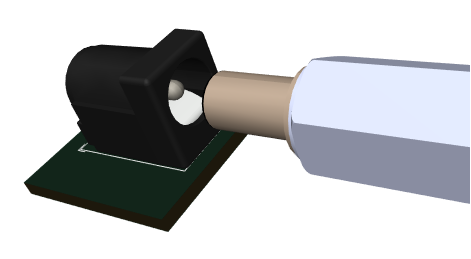

*To power the circuit, you‘ll need a 9V power supply with a DC connector.

Iată câteva sugestii:

| Conector pentru baterie de 9V + baterie |  +  | |

| Alimentator de 9V |  |

Listă cu componentele incluse în kit

| Cantitate | Nume | Detalii | Footprint | Imagine |

|---|---|---|---|---|

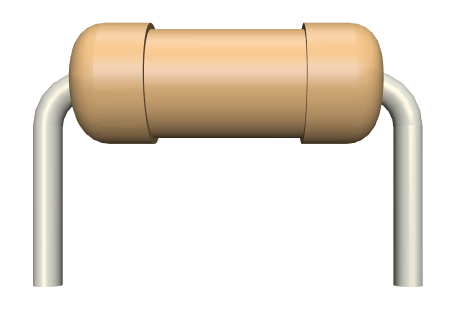

| 3 | Rezistor | 10K | R1, R2, R3 |  |

| 2 | Rezistor | 100R | R4, R5 |  |

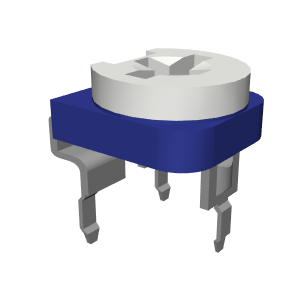

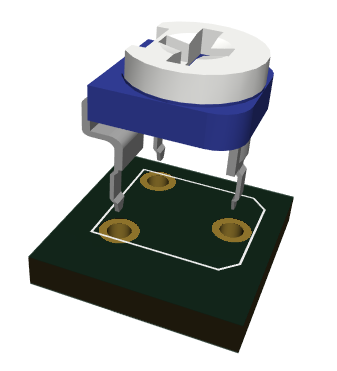

| 1 | Trimmer | 100K (104) | RW1 |  |

| 6 | Diode | 1N4148 | D1 – D6 | |

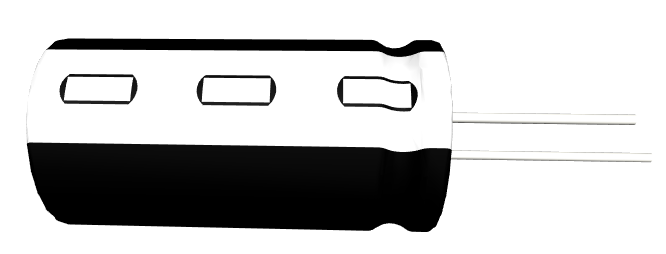

| 1 | Condensator electrolitic | 10uF | C1 |  |

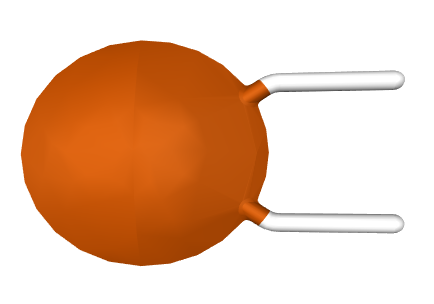

| 1 | Condensator ceramic | 10Nf (10) | C2 |  |

| 2 | Tranzistor | 8050 | Q1, Q2 |  |

| 12 | LED | roșu, 5mm | LED1 – LED12 | |

| 12 | LED | blue, 5mm | LED13 – LED24 | |

| 1 | Circuit integrat | NE555 | U1 |  |

| 1 | Circuit integrat | CD4017 | U2 |  |

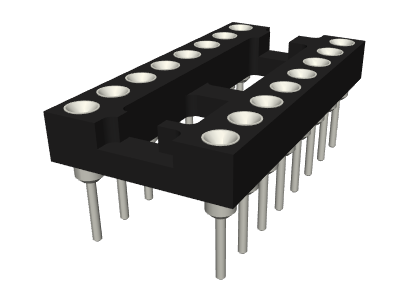

| 1 | Soclu | 8 pins | U1 |  |

| 1 | Soclu | 16 pins | U2 |  |

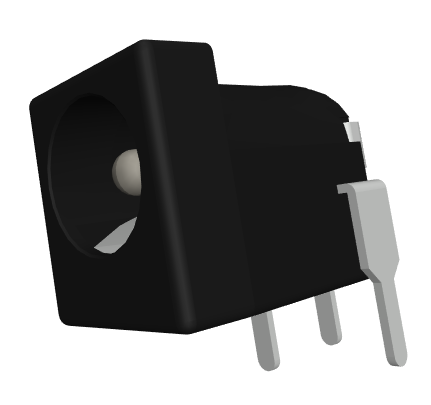

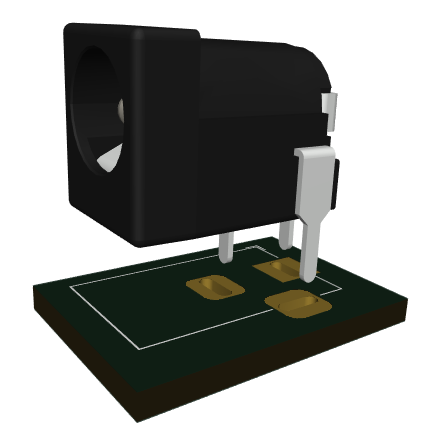

| 1 | Conector pentru alimentare | jack barrel, 9V | J1 |  |

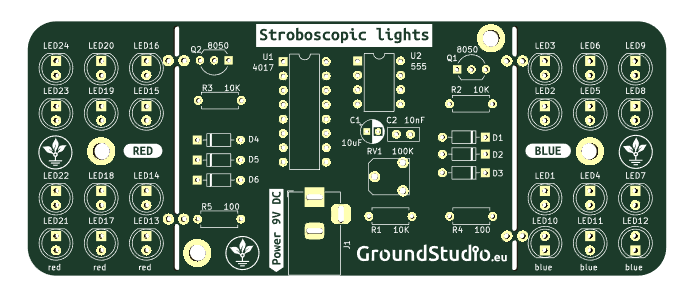

| 1 | PCB |  |

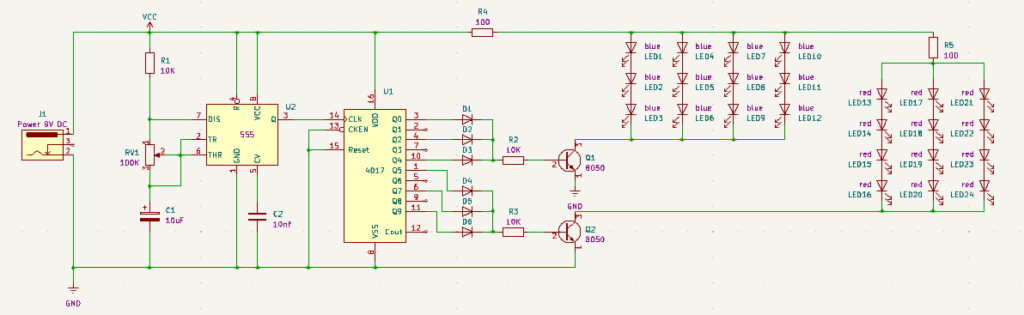

Schema electronică

Principiul de funcționare

Așa cum se poate vedea în videoul exemplu, jocul de lumini constă în două faze:

- Zona de LED-uri roșii blinkuie de 3 ori.

- Zona de LED-uri albastre blinkuie de 3 ori.

Timerul 555 este folosit ca oscilator, împreună cu R1, RV1 și C1. Acest circuit generează un impuls continuu pe pinul Q al circuitului integrat 555.

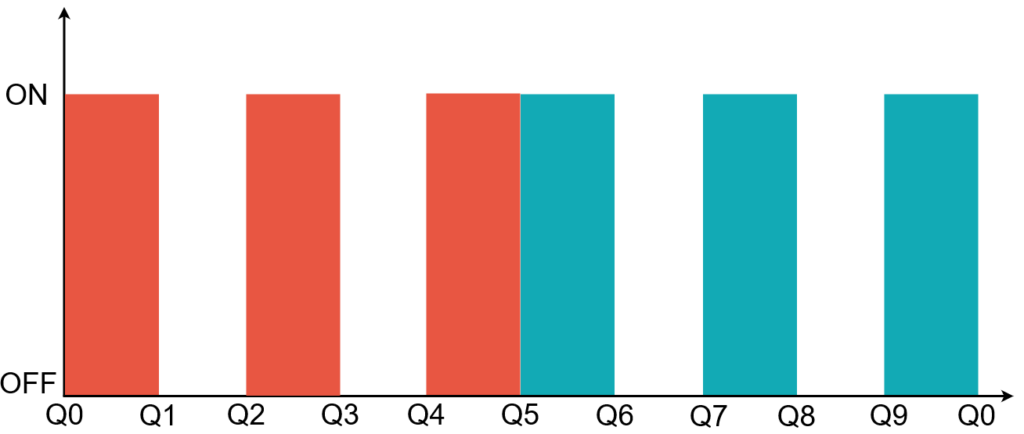

CD4017 acționează ca un contor zecimal/distribuitor de impulsuri. Mai exact, cu fiecare impuls primit de la timer la intrarea CLK, setează secvențial (pe rand) una dintre ieșirile Q, de la Q0 la Q9 pe HIGH, păstrând toate celelalte pe LOW. Așa cum se poate vedea în schema, atunci când contorul ajunge pe HIGH la Q0, Q2 și Q4, zona cu LED-uri albastre se aprinde. Similar, atunci când contorul ajunge la Q5, Q7 și Q9, zona albastră se aprinde. Atunci când contorul se află la Q1, Q3, Q6, Q8, toate LED-urile sunt stinse, deoarece toate iesirle responsabile de aprinderea LED-urilor sunt pe LOW.

Dacă te întrebi de ce LED-urile roșii sunt conectate în serie în grupuri de câte 4 și cele albastre în grupuri de câte 3, acest lucru se datorează faptului că la LED-urile roșii căderea de tensiune este mai mică decât cea la LED-urile albastre.

Graficul de mai jos ilustrează starea LED-urilor în funcție de ieșirea Q la care a ajuns contorul. Observăm că al 11-lea impuls de la timer face ca contorul să reia ciclul de la Q0, iar jocul de lumină continuă. Circuitul va continua să blinkuie atâta timp cât este alimentat.

Observă rezistorul variabil RV1. Schimbarea rezistenței acestuia va modifica frecvența impulsurilor generate de 555, făcând LED-urile să blinkuie mai rapid sau mai lent. Cu alte cuvinte, RV1 controlează viteza la care LED-urile blinkuie.

Din punct de vedere mecanic, circuitul este compus din două zone de LED-uri, una roșie și una albastră. Aceste zone pot fi separate mecanic (prin indoire sau cu ajutorul unui cleste) și conectate prin cositorire cu un cablu, dacă dorești să le relochezi. Pinii de conexiune sunt marcați ca B+ și B- pentru albastru și R+ și R- pentru roșu.

Instrucțiuni pentru pregătirea asamblării

| Pasul 0 | Citește toate instrucțiunile, de la început și până la sfârșit. |

| Pasul 1 bis | Reminder: E foarte important să citești toate instrucțiunile din acest document |

| Pasul 1 | Asigură-te că ai toate uneltele necesare asamblării kitului. |

| Pasul 2 | Asigură-te că ai toate componentele necesare asamblării kitului. |

| Pasul 3 | Pentru a respecta condițiile de garanție*, verifică/măsoară fiecare componentă în parte. |

Instrucțiuni de asamblare

| Step | Detalii | Imagine |

|---|---|---|

| Pasul 1 | Cositorește rezistorii conform marcajelor de pe PCB, indiferent de orientare. Ai grijă să respecți valorile și marcajele | |

| Pasul 2 | Cositorește diodele IN4148, astfel încât terminalul marcat negru de pe diodă (cel negativ adică) să corespundă celui de pe PCB | |

| Pasul 3 | Cositorește condensatorii electrolitici, astfel încât terminalul mai scurt (cel negativ, catodul) să corespundă zonei hașurate de pe PCB | |

| Pasul 4 | Cositorește condesatorii ceramici, indiferent de orientare | |

| Pasul 5 | Cositorește tranzistorul, astfel încât marcajele decupate să corespundă celor de pe PCB | |

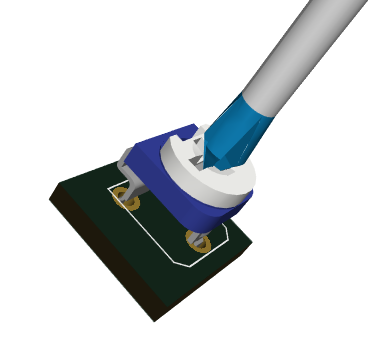

| Pasul 6 | Cositoreste trimmerul R13 conform marcajelor de pe PCB |  |

| Pasul 7 | Cositorește ledurile, astfel încât terminalul mai lung (cel pozitiv adică) să corespundă semnului "+" de pe PCB | |

| Pasul 8 | Cositorește soclurile, astfel încât marcajele decupate să corespundă celor de pe PCB | |

| Pasul 9 | Cositorește conectorul pentru alimentare conform marcajului de pe PCB |  |

| Pasul 10 | Introdu circuitele integrate 555 si 4017 in soclul lor, astfel încât marcajele decupate să corespundă celor de pe PCB | |

| Pasul 11 | Alimentează circuitul cu sursa aleasă |  |

| Pasul 12 | Verifică dacă se aprind LED-urile |  |

| Pasul 13 | Ajustează viteza cu care lumina trece de la un LED la celălalt prin rotirea lentă a trimmerului RV1 |  |

| Step 14 | Enjoy your stroboscopic lights! |  |

Instrucțiuni generale de asamblare în vederea respectării garanției

Ca o măsură de precauție și pentru respectarea condițiilor de garanție, recomandăm testarea fiecărei componente în parte înainte de momentul asamblării. De exemplu, rezistorilor li se va măsura valoarea cu un ohmmetru/multimetru. Kiturile sunt garantate pe fiecare componentă în parte, nu pe tot ansamblul. Deoarece asamblarea se face de către personal neautorizat, în condiții necunoscute sau în stadii necunoscute de finalizare, nu ne putem asuma nicio răspundere legală legată de orice urmări sau de funcționarea dispozitivelor asamblate de către orice terță parte.